OTS

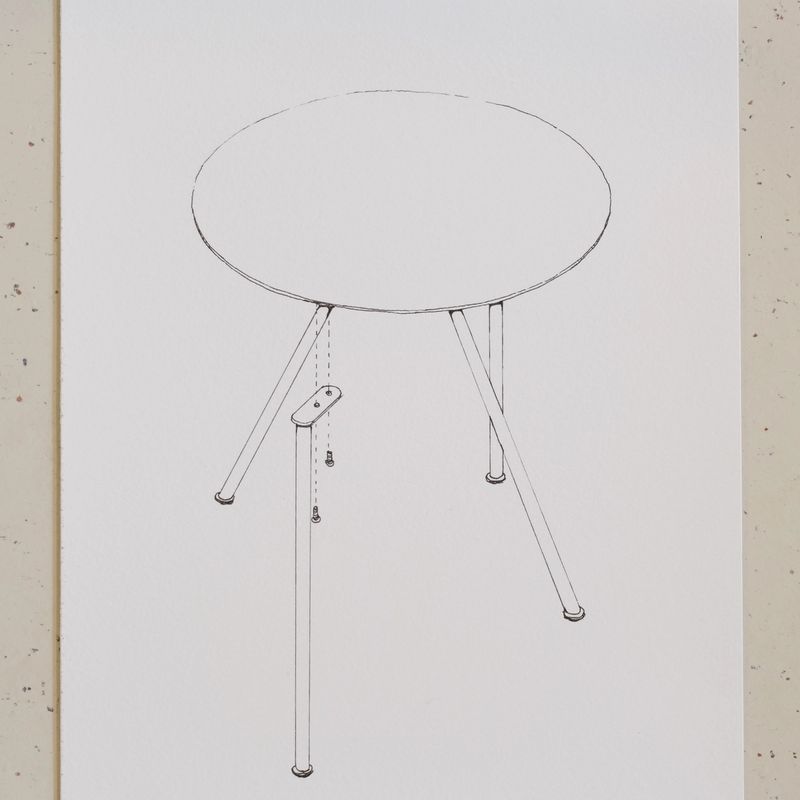

Off the Shelf (OTS) is a system where products are made entirely from standard components, sourced from maritime suppliers, hardware stores, and industrial catalogues. Each piece is assembled using simple tools: drilling, sawing, screwing, with no need for welding, custom tooling, or advanced production techniques. The component is the raw material; the user is the producer.

Why OTS exists

I created OTS because I am interested in the things we make, the way we make them and the value they bring. I come from a family of architects, and I feel deeply rooted in the Scandinavian design tradition. This tradition is inherently frugal, emphasizing the properties of each material. The architectural influence gave me an appreciation for systems, and viewing the products as part of a larger whole. OTS stems from this combination, the architectural systems thinking, and interest in the very rational evolution of the components.

Challenging the system

OTS is not a celebration of improvisation; it is a method of intent, care and discipline. At its heart, I propose this method to reclaim design from the systems that constrain it. As many design brands are being absorbed into conglomerates and private equity portfolios, they have abandoned experimentation in favour of predictable returns. Risk becomes liability, curation for the algorithm follows.

The result is a narrowing of possibilities: fewer radical ideas, fewer accessible objects, and fewer opportunities to push the industry forward. OTS proposes a counter-model, bypassing marketing, distribution, and algorithmic gatekeeping. As corporate design retreats into safe nostalgia, where experimentation cannot be justified, OTS offers a parallel space for experimental work where failure is not a liability but learning.

Ots is design as a set of recipes for anyone to make. Just as ingredients for a dish can be found in the supermarket, the ingredients for these products can be found among standard components. I call them recipes, as they are open for interpretations and adaptations.

For some reason, we accept that products come fully completed, while we would never accept this as the only choice for the food we eat. Imagine how you would feel if you could only have pre-cooked food – no recipes, no kitchens. Similar restrictions can be found in the corporate design world.

As corporate structures grow, decision time increases. What used to be a snap call by small teams based on vision and intuition becomes subject to approval by a swath of stakeholders. The result is focus-group soup, diluted concepts, and feature creep.

OTS offers freedom from this “professional” approach, bypassing the corporate busywork that views design brands as a financial asset, not an engine for improving the world.

OTS doesn’t require convincing corporate boards to make big bets; it just needs to make someone smile and think “I would like that in my life”. It does not have a stated goal of, “We must sell 50 000 units of this chair a year!” “This table must solve the home office!” or “This lamp shall inspire gen Z!”

The first series of recipes consist of two lamps, a stool, a key holder, a fruit basket, a scent disperser, a coat rack, a candle holder and a vase.

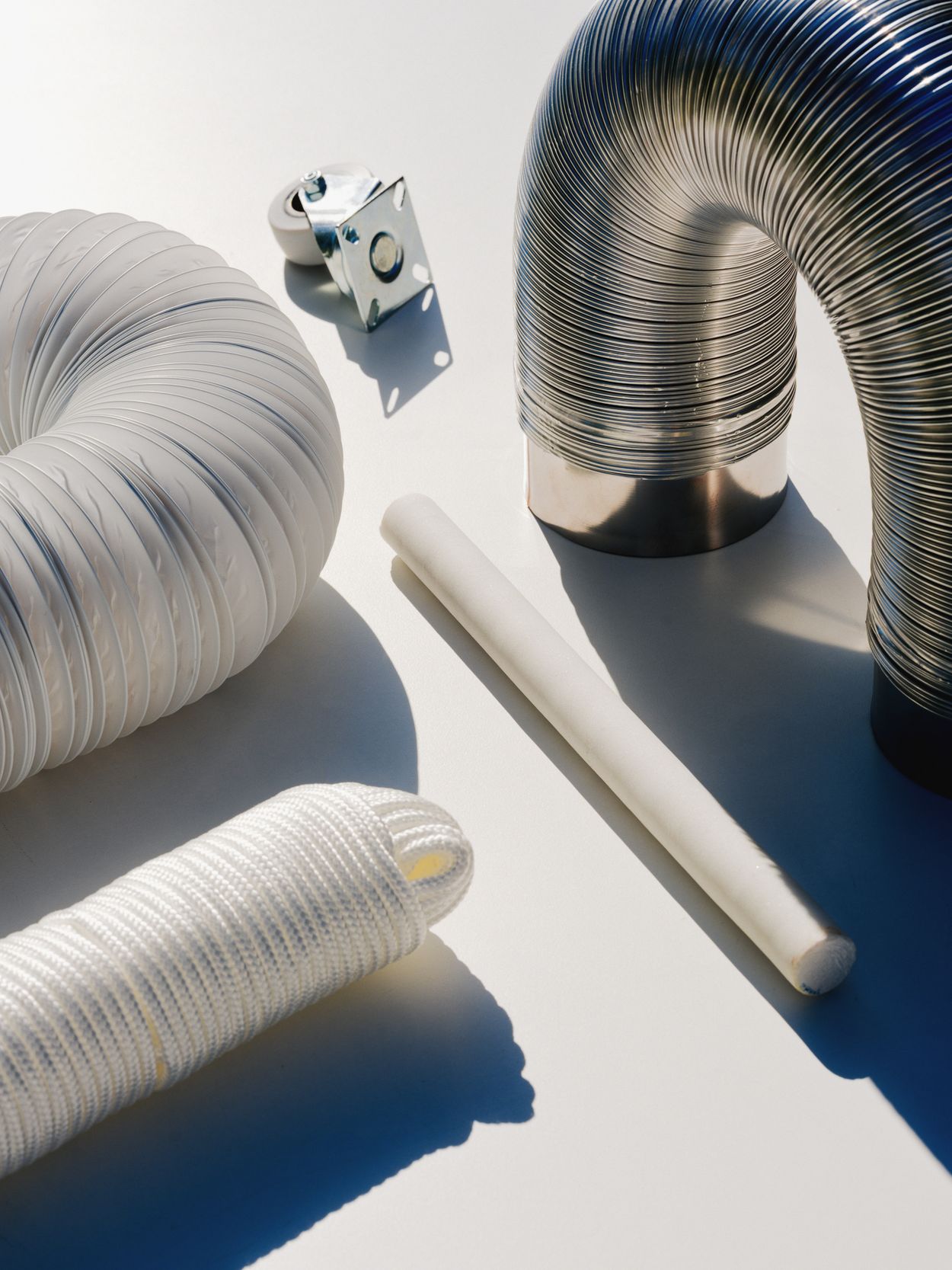

The stool is a cardboard ventilation tube with an aluminium strut inside to stiffen it up. The seat is made of tape for repairing sails, and the feet are shock absorbers for washing machines. To give it some direction, the cut of the tube is elevated in the back, and the aluminium strut inside doubles as a handle. The seat is surprisingly comfortable, and feels sturdy.

The floor lamp is made up of an anchor plate, found rocks, a ceiling cover for suspension lamp wires, an M12 bolt to seal the top, a standard LED light, and wire strips to hold the wire in place. With careful selection of the light source, this would work well as an outdoor piece. The found rocks ground the piece and enhance the profile, which has an exaggerated base and a little head.

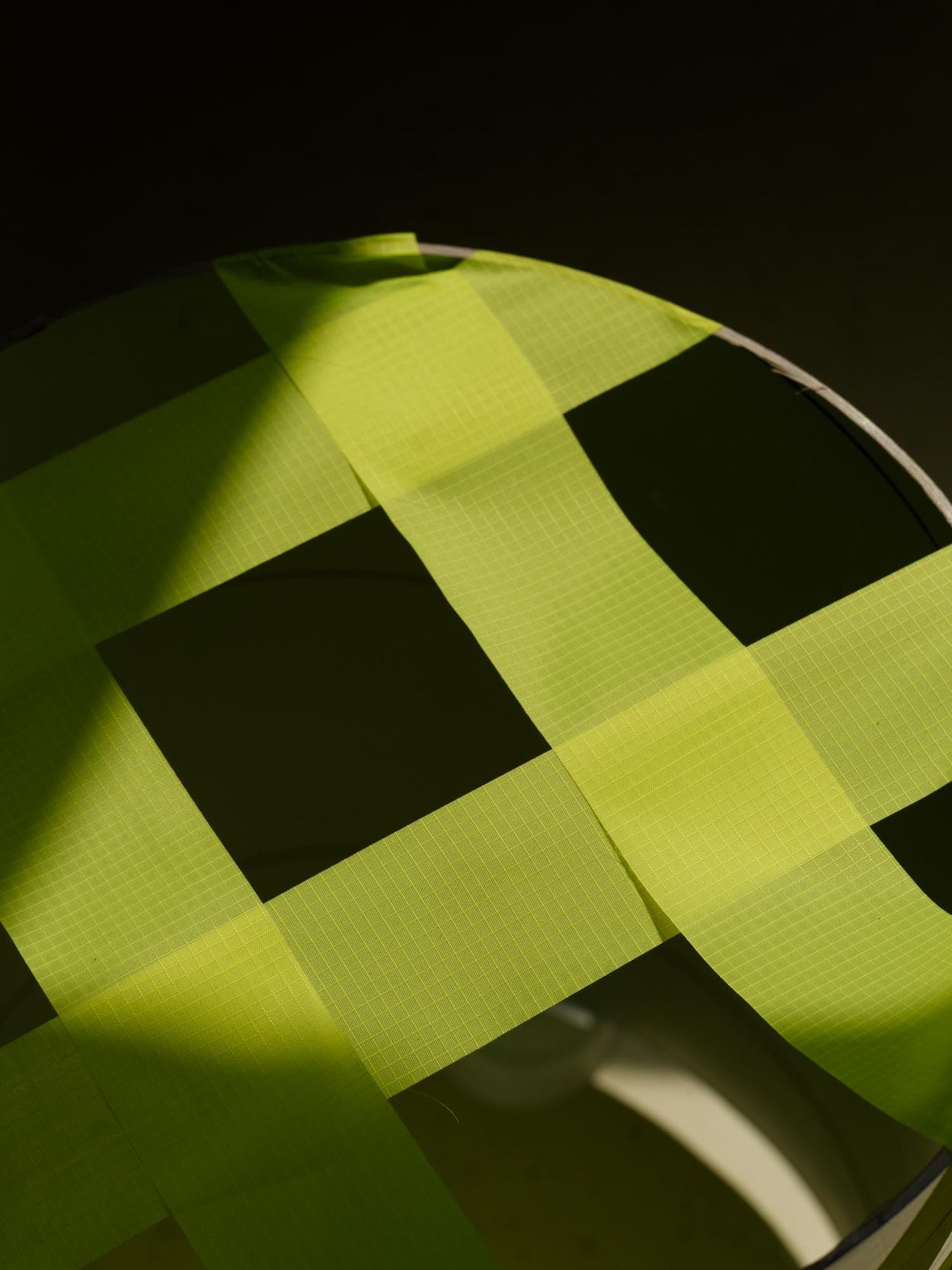

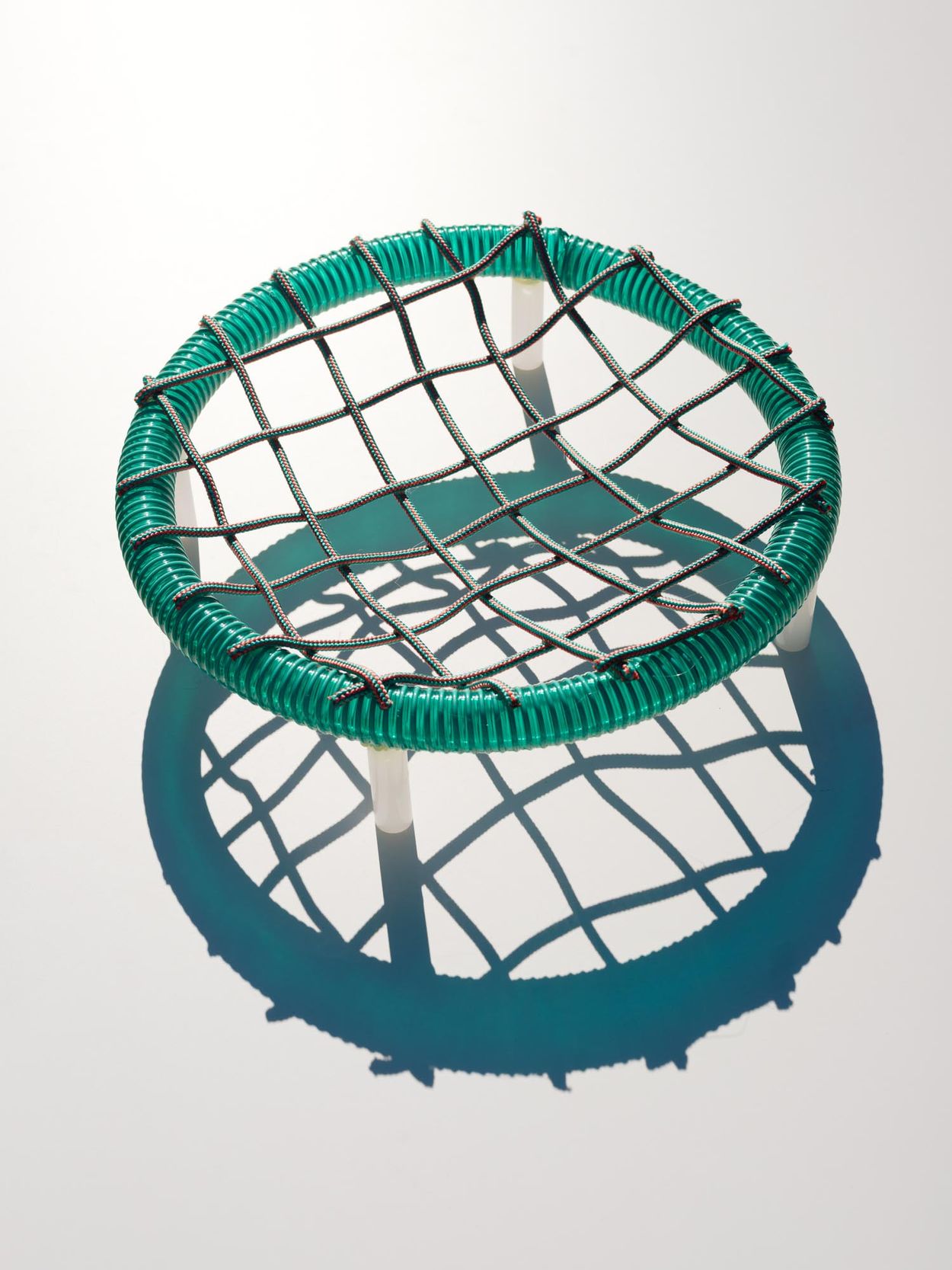

The fruit basket is made from flag line cut and glued to a corrugated tube, with precut plastic tubing as legs. The corrugated tube is cut to size with a notch at one end, and when it is pinched and inserted into the other end, the corrugated pattern acts as a catch, locking the connection in place. The open mesh lets the fruit breathe, while also hinting at weaving, a traditional basket making process.

The scent disperser is made up of a ventilation duct cover and a coconut fibre body scrub, designed to be used in the shower. Drip a couple of drops of scent in the coconut fibres and the material gently disperses it. The ventilation duct raises the coconut off the surface it is placed on, letting scent pass through. At the same time the different textures of the pieces juxtapose, and the resulting profile has a creature-like expression – always a sign of success.

The keychain holder is made up of the bent joint of a sewer pipe, a standard pre-painted fencepost base, a threaded rod cut to size, two M4 flat head Allen hex sleeve nuts, and self-adhesive rubber bumper feet. The rubber lining of the tube creates friction, helping the keys and knick-knacks to stay in place.

Design, not craft

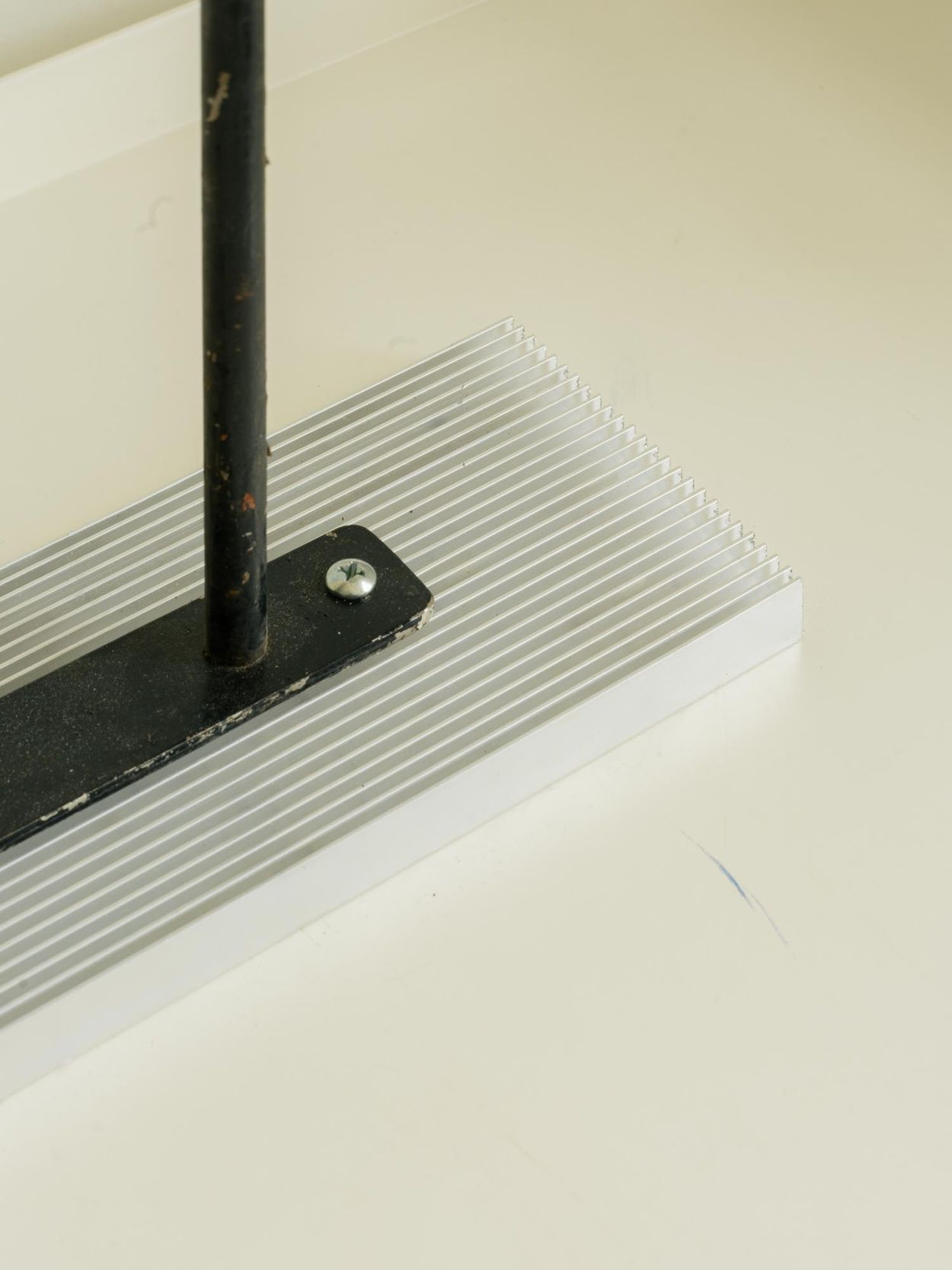

There is tremendous value in standardised components. Engineers have spent thousands of hours filing away at nuts and bolts, making incremental improvements validated by real-world application. You will not be able to easily design and manufacture a more efficient threaded rod or flag line. But by combining them in new ways you will add value, while still capturing their inherent efficiencies.

The designer in this context is not an artist or a craftsperson, but a critical thinker. The designer understands the properties of the different components and plays to their strengths. The designer will evaluate where to cut, how to stretch proportions to make them interesting, and what combinations of colour and finish will create a harmonious yet intriguing outcome. The resulting pieces should be judged on their merits as products: desirable and understandable by laypeople, robust in their production, and with their components available at an accessible price.

The Call to Action

As Big Design’s pursuit of ever-increasing returns results in sameness, OTS offers an alternative. The products offer radical open-ended ideas, inviting interpretations rather than conforming to risk-averse commercial sameness. All recipes are available to download for free and hopefully more recipes will follow, made by myself or my colleagues.

Most importantly it is my hope that you will see something you like, make it yourself, either as I have designed it, or better yet, with your own special adaptation.

- Year: 2025

- Manufacturer: OTS

- Materials: various components from industrial suppliers, maritime shops and hardware stores

- Photos: Einar Aslaksen